Behind the design is functionality

The space was engineered to provide efficient and economical solutions for a minimal carbon footprint.

Windows

We chose to work with Marvin Heritage for both the existing and new windows. Marvin's custom built heritage windows are manufactured especially where windows are to be replaced in listed, conservation and period buildings and where it is vital to retain the historical accuracy of the original window profiles.

The windows also come with the best technology in the industry in terms of superior insulation. The Low-E glazing (insulation factor equal to triple glazing) results in superior comfort inside the room, especially where large windows are installed, such as those in the main hall.

The windows also incorporate sleek engineering, from the sequential locking system through to the sophisticated rotary gear opening mechanism. The blemish-free premium wood in the window is selected for its grain and resin content to ensure quality and longevity.

Bricks

At the beginning of the project, in the demolition phase of the old reading room & scullery, we very carefully attempted to keep as mnay of the old bricks and tiles as possible.

This was critical to the "build" as we were able to use all the original materials on the front elevation.

We did however have to source a number of "special" bricks for both the window, buttress and plinth areas, as well as later on in the rebuild of the main entrance.

Lambs Bricks came to our rescue on this, and their terracotta specialist, who fortunately does not live far from the Chapel was able to carry out quite a few site visits to ensure we were on track.

Under Floor Heating

At the start of this project it became clear that the heating of the Chapel would be a project in itself.

Radiators would just not be viable, therefore after much research, and there are many people who would quite willingly give you wrong information we went with Thermo Floor UK , a subsidary of a large Dutch Company who have been operating in the UK since 1986.

With underfloor heating the heat surrounds you rather than rising from radiators and escaping through the ceiling, and in the Chapel that's critical.

Evidently, savings of approximately 20% can be made on fuel bills and maintenance is minimal.

Installation of the heating covers all areas, bar the mezzanine, the chapel is divided into six areas each controlled by a remote room thermostat.

The manifold is located in the cellar as well as the boiler so there is no visible pipework in any one area of the Chapel,

Oak Flooring

To source the flooring for Under Floor Heating was another mini project. After visiting various "Building Exhibitions" we were no clearer on what was best suited to being the most effective as well as looking the part.

Many Wood Flooring companies would suggest totally the wrong type of flooring that just would not work with under floor heating. Even though we had identified a couple of potentiail suppliers a further discussion was had with Thermo Floor and we finalised on their own supplier, Just Wood .

Finding the supplier who understood heating issues was the first step, then the actual selection of flooring was the next.

We went with a Kahrs engineered Oak board, Kahrs who have been manufacturing for 150 years understand underfloor heating more than most as it is so much more prevalent across Europe than the UK.

And as you can see, it is a superb finish, though better in the actual "flesh".

Spiral Staircases

Due to the height of the chapel gallery floor, a "standard off the shelf" spiral staircase would not suffice, so one would have to be designed & manufactured.

At first getting to grips with the complexities of a spiral is quite demanding, and it took a fair while to understand the initial designs, and layout both of the staircase and the landing exit.

Albion Spirals of Cambridge came down and surveyed the project, then manufactured and installed the staircase which is now one of the key features of the build.

Insulation

To meet the exacting requirements of present day building requirements with regard to homes being energy efficient. Insulation was a key criterion. We were fortunate in that the old walls of the existing Chapel were 9 inch brickwork either side of a cavity, which has been now pumped with insulation.

All the new structure has been built to present day regulations. However the main hall, apart from the cavity wall insulation now has been raised by 175mm to lay ground insulation to help achieve better values.

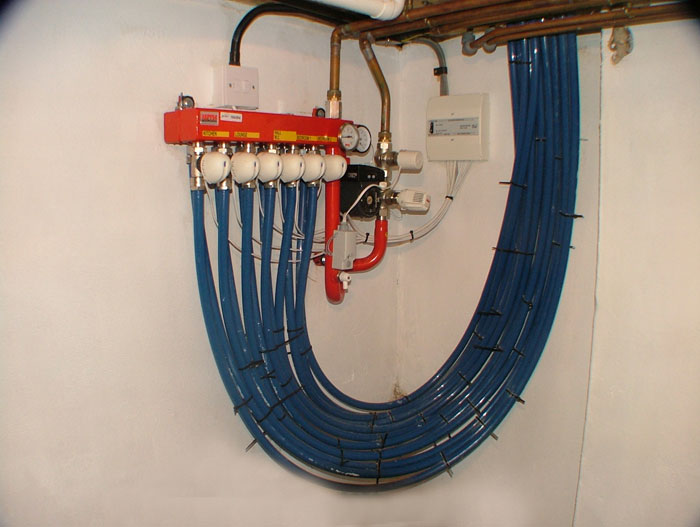

Boiler / Cellar Room Plumbing

Not the most exciting room in the Chapel, but extremely functional, housing the heating manifold together with the boiler and as you can see the only visible pipe work.

All piping / plumbing work is obviously new and guaranteed, and the boiler is a super efficient combi condensing unit. Hot water to the kitchen is provided by a separate heater & tank, as the run of pipe work from the boiler to the kitchen would have not been efficient.

Lighting & Electrics

The Chapel at night benefits from various custom designed lighting configurations to highlight the various architectural features.

All sockets, switches and panels are super thin fine quality stainless steel, and the Chapel has been wired for numerous telephone & television points with the necessary connection plates.

The Chapel has been totally rewired and meets all current legislation and is guaranteed accordingly.

Builders / Sparks / Chippy's / Structural Engineers etc

Draughtsmen - Carl Moore, Atterbury Moore 01903 871131

Builders - Amicus Building, Simon Partner 01903 247188

Structural Engineers - Philip Goacher , Paul Grinyer 01903 217723

Tiling - DH Tiling, Danny Horn 07967 333650

Electrics - CD Electrical, Chris Sene 07909 866669

Carpentry - Kevin Moore, 07841 025413

Iron Work - A.W Matthews , Tony Matthews 07802 627 695

Plumbing - Stephen Charman, 07751 451930